JIT inventory control system

Companies turnover significant inventory control to suppliers with just-in-time inventory.

Companies turnover significant inventory control to suppliers with just-in-time inventory.

Comstock/Comstock/Getty Images

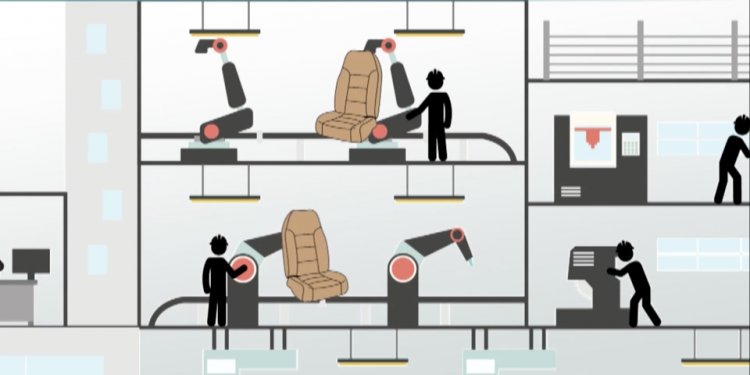

Just-in-time (JIT) inventory refers to an inventory management system with objectives of having inventory readily available to meet demand, but not to a point of excess where you must stockpile extra products. Maintaining inventory takes time and has costs, which is what motivates companies to implement JIT programs.

Customer Needs

Balancing the goals of avoiding stock outs while minimizing inventory costs is at the heart of just-in-time inventory. One of the main benefits of automated and efficient inventory replenishment systems is that you can quickly respond to reduced inventory levels. Companies are now equipped to pull back on stock in a given product category and ramp up inventory in another as customer needs and interests change.

Inventory Costs

Minimization of inventory management costs is a primary driver and benefit of just-in-time practices. Inventory management has costs, and when you reduce the amount of holding space and staff required with JIT, the company can invest the savings in business growth and other opportunities, points out the Accounting for Management website. You also have less likelihood of throwing out product that gets old or expires, meaning reduced waste.

Coordination

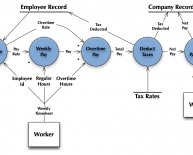

A disadvantage of managing a just-in-time inventory system is that it requires significant coordination between retailers and suppliers in the distribution channel. Retailers often put major trust in suppliers by syncing their computer systems with suppliers so they can more directly monitor inventory levels at stores or in distribution centers to initiate rapid response to low stock levels. This usually means build up of technology infrastructure, which is costly. This coordinated effort is more involving on the whole than less time intensive inventory management systems.

Risks

Just-in-time inventory is not without risks. By nature of what it is, companies using JIT intend to walk a fine line between having too much and too little inventory. If company buyers fail to adjust quickly to increased demand or if suppliers have distribution problems, the business risks upsetting customers with stock outs. If buyers over compensate and buy extra inventory to avoid stock outs, the company could experience higher inventory costs and the potential for waste.