Inventory control Systems tools

Inefficient inventory management can ruin your business. Be aware that we’re all prone to making costly mistakes that can spell the end for your business. Even Nike wasn’t immune. In early 2000s, lack of inventory control led to the loss of, hold your breath, approximately $100 million in sales.

Fortunately, they were able to bounce back by using a better inventory management system.

If it can happen to one of the biggest companies in the world, it can happen to you too.

We’ve rounded up the top 5 inventory management mistakes businesses make and the possible solutions:

Failure To Accurately Forecast Demand

Nike’s problem stemmed from inaccurate forecast demand. Its software had bugs and errors and produced erroneous forecast, which they used for their manufacturing plan. As a result, they didn’t have enough products their customers wanted and overproduced on items that were not sold.

Inventory management systems, first and foremost, must be free from bugs and data errors. Demand forecasts are critical to producing the right number of items and if the calculations are off, you’re in trouble. The answer is very simple: invest in an inventory tracking software that provides accurate data, like Tradegecko.

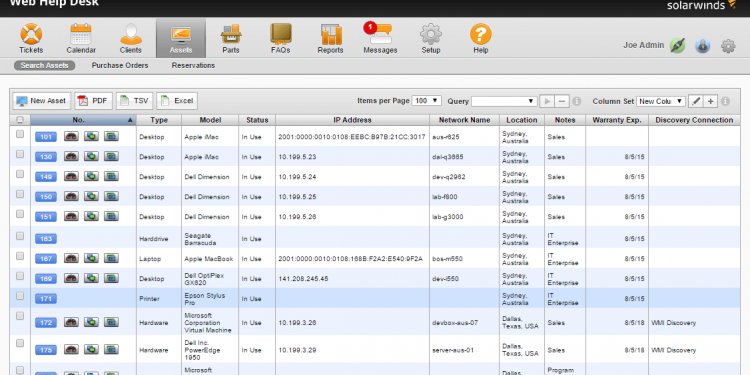

Lack Of Automation

If you’re still tracking inventory with Excel, then you could be losing money. Manual tracking takes too much time and won’t get you results. You’re wasting resources and that keeps you from focusing your energy on other areas that can help grow your business.

Sterling Lighting, a company that specializes in LED light bulbs and outdoor lighting applications, saved a lot of money by using a cloud based inventory management software that helped them automate tasks. They were able to cut down on unnecessary labor costs and subsequently were able to spend more time focusing on growth.

Improper Training

For most companies who are still using software that’s installed on local computers, issues are common because not everyone knows how to use it properly. When there’s so much to do and only one person who’s familiar with the system, you can get left behind in orders. Lack of proper training can severely affect your ability to keep up with orders.

Cloud-based inventory management systems are beneficial in so many ways:

- They have easier learning curves and it shouldn’t take long to train employees properly.

- Easy access even for those who travel a lot.

- No need to have separate people process orders, check stock, or track inventory. NZ-based jeweler Nick Von K found inventory management very annoying and unproductive because it divided his team’s time between administrative tasks and stock management but by using an online inventory management tool, they were able to streamline their operations and focus on expanding the business.