Warehouse control system Software

What Is WMS Software?

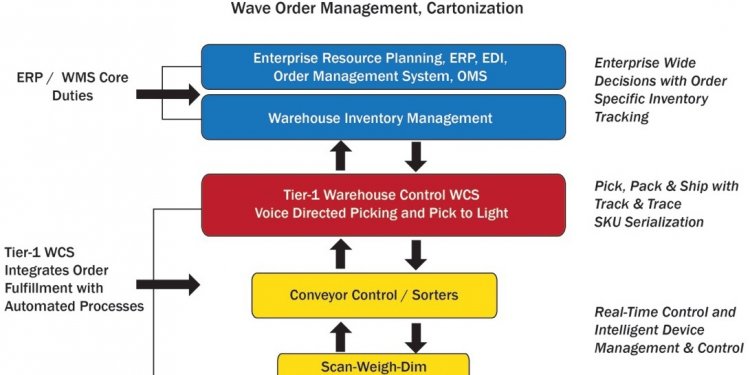

As supplies move through the warehouse/distribution center, managers must track inventory and ensure that products are picked and put away in a productive and expedient manner. Warehouse management systems (WMS) help users improve the efficiency of these inventory control operations.

Warehouse inventory software should provide managers with the tools they need to analyze stock and makes plans for inventory movement or replenishment. Used alongside a transportation management system, WMS systems serve as a critical part of an overall supply chain management system. To see additional product reviews and comparisons, visit www.WarehouseManagementSystemsGuide.com.

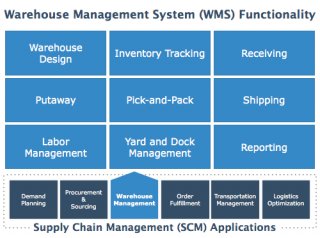

The core functionality of most warehouse management systems help warehouse managers and workers guide inventory through receiving, putaway, picking, packing and shipping.

Functionality

Description

Warehouse design

Warehouse design functionality allow users to customize workflow and picking logic to ensure that inventory is allocated to the correct location within each facility. The WMS establishes correct bin slotting to maximize warehouse space and account for seasonal inventory variance.

Inventory tracking

Most systems offer the ability to use advanced tracking systems, such as auto ID data capture (AIDC), barcode scanners or radio-frequency identification (RFID) to ensure that inventory is correctly logged and easily located when the time comes for it to move.

Receiving and putaway

Once inventory is logged, warehouse management systems assist with inventory putaway for retrieval at a later date. More advanced systems offer pick-to-light (light-picking) and pick-to-voice (voice-picking) technology to aid more sophisticated warehouse environments.

Pick-and-pack

Warehouse management systems often contain a variety of options like zone picking, wave picking and batch picking to provide managers greater flexibility. Additionally, lot zoning and task interleaving help workers reduce the number of trips necessary to complete a task.

Shipping

Once inventory is packed, the WMS can send itemized bills of lading (B/L) ahead of the shipment, generate packing lists and invoices for buyers to reconcile items shipped with items ordered, and even include assembly instructions if needed. Once items have been packed, the warehousing software can send advanced shipment notifications (ASN) to notify other facilities of pending deliveries.

Labor management

Labor performance modules also help managers monitor worker efficiency and performance. Key performance indicators (KPIs) help managers keep tabs on the workers who are performing above and below standard.

Yard and dock management

A common feature in WMS software, yard management assists trucks as they come-and-go and find the correct loading docks. Some applications also help manage cross-docking, or the ability for incoming trucks to be unloaded and loaded concurrently.

Reporting

Advanced reporting features within the software can help managers analyze the performance of the operation as a whole and find areas for improvement. For example, the system can automatically analyze cycle counts, which count a different subset of inventory each day.

Functionality

Description

Warehouse design

Warehouse design functionality allow users to customize workflow and picking logic to ensure that inventory is allocated to the correct location within each facility. The WMS establishes correct bin slotting to maximize warehouse space and account for seasonal inventory variance.

Inventory tracking

Most systems offer the ability to use advanced tracking systems, such as auto ID data capture (AIDC), barcode scanners or radio-frequency identification (RFID) to ensure that inventory is correctly logged and easily located when the time comes for it to move.

Receiving and putaway

Once inventory is logged, warehouse management systems assist with inventory putaway for retrieval at a later date. More advanced systems offer pick-to-light (light-picking) and pick-to-voice (voice-picking) technology to aid more sophisticated warehouse environments.

Pick-and-pack

Warehouse management systems often contain a variety of options like zone picking, wave picking and batch picking to provide managers greater flexibility. Additionally, lot zoning and task interleaving help workers reduce the number of trips necessary to complete a task.

Shipping

Once inventory is packed, the WMS can send itemized bills of lading (B/L) ahead of the shipment, generate packing lists and invoices for buyers to reconcile items shipped with items ordered, and even include assembly instructions if needed. Once items have been packed, the warehousing software can send advanced shipment notifications (ASN) to notify other facilities of pending deliveries.

Labor management

Labor performance modules also help managers monitor worker efficiency and performance. Key performance indicators (KPIs) help managers keep tabs on the workers who are performing above and below standard.

Yard and dock management

A common feature in WMS software, yard management assists trucks as they come-and-go and find the correct loading docks. Some applications also help manage cross-docking, or the ability for incoming trucks to be unloaded and loaded concurrently.

Reporting

Advanced reporting features within the software can help managers analyze the performance of the operation as a whole and find areas for improvement. For example, the system can automatically analyze cycle counts, which count a different subset of inventory each day.

Other Applications to Consider

Just because you have a warehouse doesn't mean you need warehouse management software. It may be overkill for your needs. Instead, there are several related applications available that address specific problems in the supply chain.

If you don’t need a solution to automate picking, putaway, docking or worker responsibilities, an inventory management solution may be a better investment. Solutions from IntelliTrack and Fishbowl are some of the more highly reviewed products. Order fulfillment software is best for buyers looking to improve the management of their order-to-cash process. Many WMS and TMS software solutions contain order fulfillment functionality within their systems, but buyers without the need to automate warehousing or transportation tasks should evaluate order fulfillment applications. NetSuite, Epicor and SAP offer popular order fulfillment modules. For buyers who want to improve transportation/freight and risk analysis, a logistics software application may be a better fit. These applications often include the functionality to manage all aspects of supply chain execution (SCE) tasks: planning, procurement, warehousing and transportation. CMS Professional and TMW Systems are popular logistics software solutions.Best-of-Breed WMS vs. Integrated Suite

Buyers need to decide if they want to purchase a best-of-breed WMS or an integrated suite of applications. Typically, best-of-breed applications have deeper functionality than modules within integrated suites. In this case, that means more picking configurations, labor management features, built-in integrations with other technologies and other warehouse-specific features within best-of-breed applications than WMS modules within supply chain management or Enterprise Resource Planning (ERP) suites.

Alternatively, buyers may want to evaluate integrated suites if they want a solution that can manage other aspects of the business (accounting, human resources, manufacturing, customer management etc.) in addition to the warehouse. These vendors are also typically more stable, meaning buyers won’t have to worry about their provider going out of business or being acquired by another vendor.

Evaluating WMS Software

Since the whole point of warehouse software is to reduce spending, buyers should focus first and foremost on the total cost of ownership. Fortunately, vendors have become more competitive in this area, just as they are competing on functionality and, more recently, application architecture configurability.

Each vendor will claim that their warehouse management system software provides more opportunities to expand on out-of-the-box functionality than their competitors. Systems that can truly offer the most advanced functionality, optional features for specific vertical markets, configurable architecture and competitive cost of ownership will have the greatest chance of winning over buyers.

Specific questions to ask when selecting a WMS system include:

- Does the system offer industry-specific functionality for the unique needs of your operation? If not, can it be configured to meet those needs?

- Will a new WMS system provide the necessary cross-functionality with your existing logistics solutions (TMS, order fulfillment etc.) to manage your end-to-end processes (i.e., order to cash)?

- Do you want an on-premise, client/server-based deployment, or is your organization interested in exploring Web-based deployment opportunities?

- Will the user interface be accessible and easy-to-learn for less experienced staff members?