September 15, 2018

Quality control Systems Manager

All 25 displayed

- Collect and analyze production samples to evaluate quality.

- Analyze quality control test results and provide feedback and interpretation to production management or staff.

- Stop production if serious product defects are present.

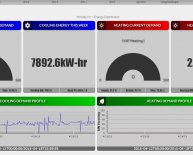

- Monitor performance of quality control systems to ensure effectiveness and efficiency.

- Communicate quality control information to all relevant organizational departments, outside vendors, or contractors.

- Instruct staff in quality control and analytical procedures.

- Produce reports regarding nonconformance of products or processes, daily production quality, root cause analyses, or quality trends.

- Participate in the development of product specifications.

- Review statistical studies, technological advances, or regulatory standards and trends to stay abreast of issues in the field of quality control.

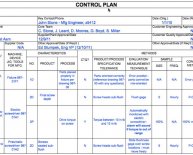

- Identify critical points in the manufacturing process and specify sampling procedures to be used at these points.

- Create and implement inspection and testing criteria or procedures.

- Oversee workers including supervisors, inspectors, or laboratory workers engaged in testing activities.

- Document testing procedures, methodologies, or criteria.

- Review and update standard operating procedures or quality assurance manuals.

- Identify quality problems or areas for improvement and recommend solutions.

- Verify that raw materials, purchased parts or components, in-process samples, and finished products meet established testing and inspection standards.

- Review quality documentation necessary for regulatory submissions and inspections.

- Generate and maintain quality control operating budgets.

- Direct the tracking of defects, test results, or other regularly reported quality control data.

- Evaluate new testing and sampling methodologies or technologies to determine usefulness.

- Direct product testing activities throughout production cycles.

- Instruct vendors or contractors on quality guidelines, testing procedures, or ways to eliminate deficiencies.

- Coordinate the selection and implementation of quality control equipment, such as inspection gauges.

- Monitor development of new products to help identify possible problems for mass production.

- Confer with marketing and sales departments to define client requirements and expectations.